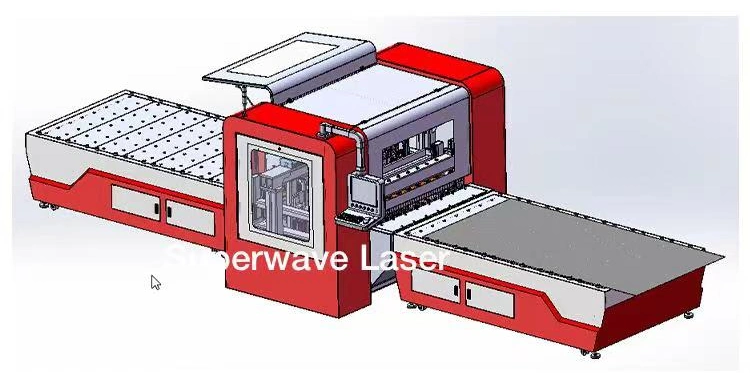

Pillow Plate Laser Welding System: Advanced Manufacturing Solution

Pillow Plate Laser Welding System: Advanced Manufacturing Solution Pillow Plates are heat exchanger plates that can be u

Basic Info.

| Model NO. | SW-CW |

| Laser Classification | Optical Fiber Laser |

| Type | Automatic Laser Welding Machine |

| Support | Dxf, Plt, etc |

| Applied to | Single Embossed and Double Embossed |

| Thickness | Above 0.5mm |

| Pillow Plate Design | Support Square and Cicular Shapes with Any Designs |

| Materials | Stainless Steel, etc |

| Delivery | 70-80 Working Days |

| Applications | Manufacturing Tanks, Vessels, and Other Industrial |

| Customization | OEM |

| Certificate | CE, FDA |

| Laser Type | Fiber Laser |

| Transport Package | Standard Export Packing |

| Specification | 10CBM |

| Trademark | SUPERWAVE LASER |

| Origin | China |

| HS Code | 8468800000 |

| Production Capacity | 100sets/ |

Product Description

Pillow Plate Laser Welding System: Advanced Manufacturing Solution

Pillow Plates are heat exchanger plates that can be used for industrial cooling or heating of a variety of products. These laser welded plates have endless applications in different industries, including cooling milk, soft drinks, wine or beer. They are also used in various other sectors like the meat processing, chemical and pharmaceutical industries.

Advantages of laser welded pillow plates:

- Faster production with less material;

- Laser welding is based on the principle of melting the basic material without any direct mechanical contact with the processed surface;

- All welds are extremely accurate and consistent, any additional weld finishing is not needed;

- Laser welding enables various welding lines, welding of spirals and irregular forms; any openings and connectors on the basic surface can be easily avoided;

- Welds are not deep and are made with low heat input which reduces the possibility of any deformations of the basic material; And the inner surface of the jacket retains its initial shape after welding;

- A better through-flow of the cooling medium gives a higher cooling effect;

- A simple adjustment of the pillow plate surface to various connectors on the jacket tank (door, fittings and other connectors) without losing the cooling surface;

- Quality and aesthetic design; all welds retain the metal shine of the basic material;

- As any shape can be designed and welded, tailored solutions can be created;

- Fully automated welding-process with low cost of labor and high-quality end product.

Technical Data

| Laser model | SW-PLW |

| Laser power | 3000W/4000W/6000W Fiber laser source |

| Range of power adjustment | 5-95% |

| Laser wavelength | 1070±5nm |

| Motion units | High accuracy guide rail with precision grinding ball screw or gear rack system, all are famous brand which import from Japan or Germany. |

| Laser Machine Base | High strength steel welding machinery base with heat treatment. Fly type laser optical path rail design, easy to load and unloading work piece. |

| CNC Drive & control system | All are Servo motor drive by Japan. Reduction gear from Japan. CNC system is Designed in Germany. Assembly in China. |

| Pillowplate welding workbench | Dimension customized according to Pillowplate Design by Superwave laser Corp. Easy to load and unloading. with special jig and vacuum systems. |

| Cooling system | Water chiller |

| Power supply | AC380V/50-60Hz |

| Working environment humidity | ≤95% |

| Working environment temperature | 10-35ºC |

Samples

- Why choose laser welding?

Laser is energetic, because for the same welded thicknesses, with resistance it is necessary to install systems with a power of 300 kW, of which 200kW is absorbed. With lasers, only 30 kW are needed, so in this case in terms of energy costs we are at a ratio of 1 to 10. Ultimately, laser welding has a high initial plant cost, but the so-called "life cycle cost" is very low, and in fact within a short time it is possible to amortize this cost.

The laser also makes the product more resistant in thermally altered areas, allowing greater corrosion and mechanical resistance of the welded materials.

Laser welding pillowplate is the general trend and the inevitable result of industrial upgrading.

2. What Superwave Laser can offer you?

- Equipped with imported laser source, more durable, support 24x7 uninterrupted production;

- High cost performance, Initial investment cost less than 1/5 of imported brands, high-quality welding and almost the same production efficiency;

- With more than 10 years of practical experience, the equipment has been exported to many foreign regions. Our rich experience will bring you put into production quickly;

- Perfect and lasting after-sales service, as long as you need it, we are always by your side to provide you with a positive response;

- Continuous R&D investment, to provide you with software upgrade services.

Send to us