Automatic Robotic Metal Laser Welder Automated Steel Robot Laser Welding Machine Price

Package Size 1460.00cm * 1090.00cm * 1240.00cm Package Gross Weight 520.000kg Automatic Robotic Metal Lazer Welder Equip

Basic Info.

| Model NO. | DV-LWR |

| Technical Class | Continuous Wave Laser |

| Control | Automatic |

| Power Density | Deep Fusion Welding |

| Laser Classification | Optical Fiber Laser |

| Type | Optical Fiber Transmission Laser Welding Machine |

| Business Type | Manufacturer; Factory |

| Fiber Laser Soure | Max, Raycus, Jpt, Ipg |

| Working Radius | 1720mm |

| Robot Arm | 1.8m |

| Selling Point | Easy to Operate, Low Consumption |

| Robot Axis | 6 Axis |

| Auxiliary Gas | Argon, Nitrogen |

| Laser Power | 1500W, 2000W, 3000W |

| Power Supply | 220V, 50-60Hz |

| Cooling Mode | Water Cooling |

| Applied Material | Stainless Steel, Aluminum, Steel, Galvanized Sheet |

| Laser Type | Continuous Laser, Constant Laser |

| Wire Filling | with Wire Filler Machine |

| Cable Length | 10m or Customized |

| Certificate | CE FDA |

| Transport Package | Wooden Box |

| Specification | 2-3CBM |

| Trademark | D. Ventus |

| Origin | China |

| HS Code | 8515809090 |

| Production Capacity | 50 Sets Per Month |

Packaging & Delivery

Package Size 1460.00cm * 1090.00cm * 1240.00cm Package Gross Weight 520.000kgProduct Description

Automatic Robotic Metal Lazer Welder Equipment Automated Steel Aluminum Robot Laser Welding Machine Price

SPECIFICATIONS:

| Model | DV-LWR | Robot Model | RH18 |

| Laser Power | 1500W/2000W | Arm Wingspan | 1.8m |

| Axis Type | 6 Axis | Load Capacity | 20kg |

| Schematic | 6m | Fiber Cable Length | 10m |

| Laser Source | Maxphotonics | Welding Head | Chaoqiangweiye |

| Water Chiller | S&A | Welding system | Chaoqiangweiye |

| Model | DV-LWR |

| Input Power | 3~380V±15%,50/60HZ |

| Input Power | 9KW |

| Laser Power | 1500W/2000W |

| Laser Length | 1080nm |

| Optical Fiber Length | 10m |

| Optical Core Diameter | 50μm |

| Welding Speed Range | 0-120mm/s |

| Working Temperature Range | -10°-40° |

| Welding Thickness | 0.5-4mm |

| Cooling Method | Water Cooling |

| Dimension | 954×715×1080mm |

| Total Weight | 170KG |

| Consumables | Protect lens, nozzles |

| Total Power | 9KW |

| Filling Material | 0.8mm, 1mm,1.2mm,1.6mm SS/CS/AL |

| Maximum joint speed | Axis 1 159°/S |

| Axis2 159°/S | |

| Axis 3 159°/S | |

| Axis 4 280°/S° | |

| Axis 5 240°/S | |

| Axis 6 520°/S |

| Torque Tolerance | Axis 4 48N.m |

| Axis 5 48N.m | |

| Axis 6 28N.m |

| Inertial Momentum Tolerance | Axis 4 1.8kg.m2 |

| Axis 5 1.8kg.m2 | |

| Axis 6 0.8kg.m2 |

WELDING CAPACITY:

| Laser Power | Material | Max. Penetration Thickness | Max. Welding Thickness |

| 1KW | SS/CS | 3mm | 4mm |

| AL/GI | 1mm | 2mm | |

| 1.5KW | SS/CS | 4mm | 5mm |

| AL/GI | 2mm | 3mm | |

| 2KW | SS/CS | 5mm | 6mm |

| AL/GI | 3mm | 4mm |

MAIN COMPONENTS

- It can precisely control the welding process, including parameterization, anti-sticking treatment of wire filler, etc..

- Specially designed welding instruction is available to reduce programming time;

- Can be equipped with off-line software for offline programming;

Schematic of 8-inch TFT-LCD, keyboard+touch screen mode select switch, safety switch, emergency stop button

ADVANTAGES:

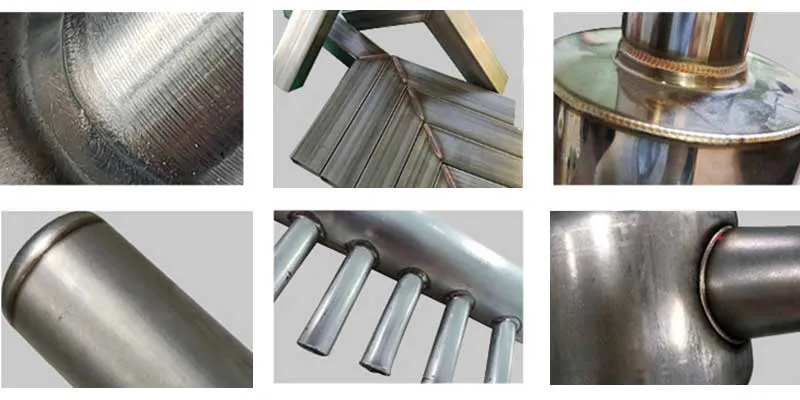

- Water cooled laser head, which is of ergonomic design, flexible to operate. It achieves spot welding, butt welding, stitch welding, inner and outer angle welding, seal welding.

- Good quality fiber laser source is of fine laser beam and small focus spot, which contributes to high positioning accuracy, fast welding speed and small seam. It offers effective and perfect welding solutions for customers.

- The welding finish is not easy to deform. The effective penetration make the welding solid.

- Display screen is equipped to observe the welding process and position.

- Precision wire filler device is equipped for thicker welding.

SAMPLE &APPLICATION:

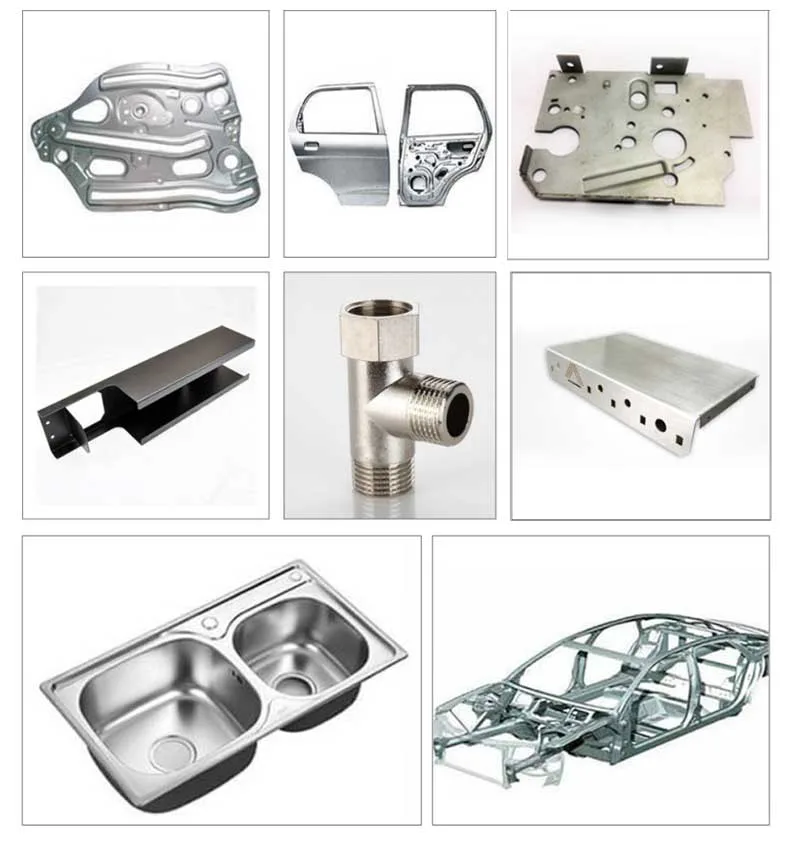

It can be widely used in complicated and irregular welding processes in cabinets, kitchens and bathrooms, staircase elevators, shelves, ovens, stainless steel door and window guardrails, power distribution boxes, stainless steel household appliances and other industries. It can applied to stainless steel, iron sheet, aluminum, copper, alloy, steel, galvanized,etc.

ABOUT US:

Jinan D.Ventus Mechanical Equipment Co., Ltd is a privately owned company from china. As an enterprise with core technology and independent intellectual property rights, we are committed to the development and manufacturing of CNC laser machines (Fiber laser cutting machine, fiber laser cleaning machine, fiber laser welding machine, laser marking machines), CNC spare parts and other powder coating equipment. Well-equipped with CNC machinery and strong technical force, we welcome OEM and ODM orders. We guarantee the stable and timely delivery, reliable quality, and timely on-site training and after-sales service. We offer products approved by SGS enterprise certification, CE Certifications, design patents.We strictly conform with industrial process and safety guidance by CE and ISO9001 to offer high quality machines. All of machines are fully assembled and thoroughly tested and checked prior to shipment.

Our products have good reputations both domestically and abroad. Our products have been exported to America, Australia, Argentina, Mexico, Malaysia, Paraguay, Russia, Pakistan, Brazil, Ethiopia, Tunisia, Vietnam, Indonesia, Bulgaria, India, Jordan, Mongolia, etc.

We offer 24 hours online support for customers all over the world. Clients' satisfactions are our always goals to persue. We provide upgrades and maintenance for software system within warranty period. And also we provide technical maintenance and repair for third-party hardware and software products according to third-party manufacturer's warranty-grade.

Guarantee:2 years warranty for the whole machine. Within 24 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free. After 24 months, you will get spare parts at cost price. You will also get technical support and service all the lifetime.Technical support:1. Technical support by phone, email or WhatsApp/Skype around the clock.2. Friendly English version manual and operation video CD disk.3. If needed, we can send our engineer to your site for training or you can send the operator to our factory for training.After sales services: Normal machine is properly debugged before dispatch. You will be able to use the machine immediately after receiving the machine. Besides, you will be able to get free training advice . You will also get free suggestion and consultation, technical support and service by email/WhatsApp/wechat etc.

Send to us